Principle of PVD Technology and Sterilization

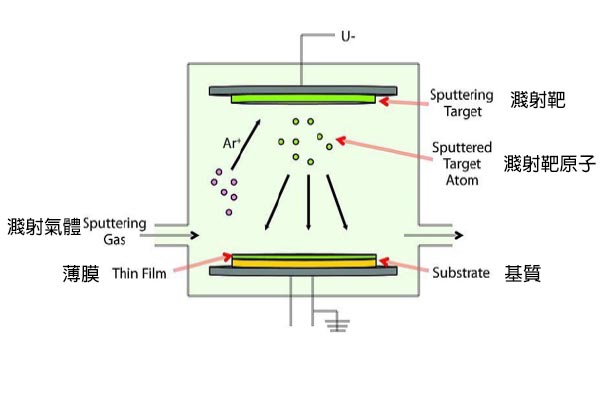

Nano-Antibacterial Coating Film is made by Physical Vapor Deposition (PVD) technology. It is made through a high voltage electric field in a vacuum, which generates argon-ion flow, sputter nano-silver, forming a thin layer of film after precipitation and accumulation. The film made by PVD perfectly integrates nano-silver to form a complete and smooth surface film. The whole process does not add any chemical elements, not only will not produce pollutants, it will not stimulate the human body which causes allergies.

“Nano-silver” is verified to be able to kill 650 types of virus.

Nano-silver generates silver ions when in contact with air and moisture. The positive ions have an absorption effect towards micro-organisms, and the diameter of the sterilization capacity is 2mm, damaging cell membranes and enzymes to achieve the function of killing bacteria. When the bacteria is killed by silver ions, silver ions free themselves from the dead bacteria and continue to do the same to the living bacteria until all bacteria are destroyed.

Nano-silver generates silver ions when in contact with air and moisture. The positive ions have an absorption effect towards micro-organisms, and the diameter of the sterilization capacity is 2mm, damaging cell membranes and enzymes to achieve the function of killing bacteria. When the bacteria is killed by silver ions, silver ions free themselves from the dead bacteria and continue to do the same to the living bacteria until all bacteria are destroyed.

Nano-Antibacterial Coating Film had ran tests and is confirmed to be free of carcinogen, alcohol, drugs and toxicity. It operates physically by the energy of silver ions, and will be effective on the contact surface of the film for just 10 seconds. It can be used normally as long as the film surface remains intact.